Our next meeting should be on the 12th November 2020, it was to be organised by Cliff Sim but due to the ongoing Covid-19 restrictions this meeting will now be a virtual meeting. Cliff had wanted the meeting to feature making boxes, we can still make some boxes for Cliff, all you have to do is make a box or 2, any shape any size, once made photograph them and send the pictures to me for publication, give me some info on your box or boxes, things like the size and the wood it’s made from.

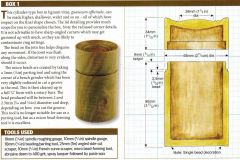

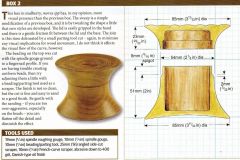

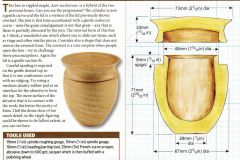

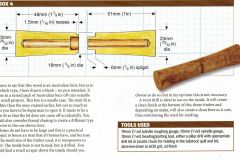

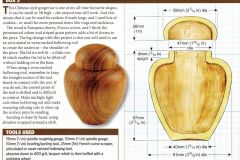

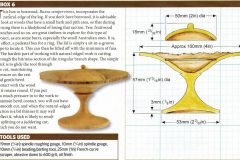

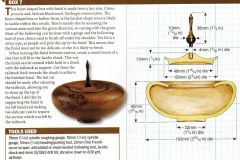

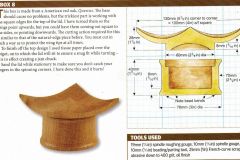

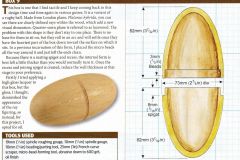

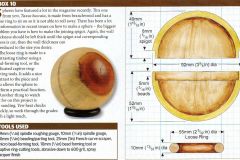

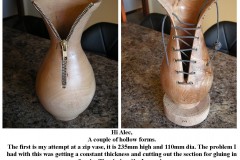

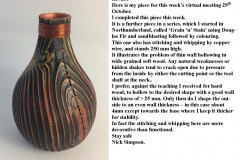

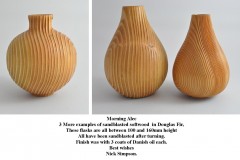

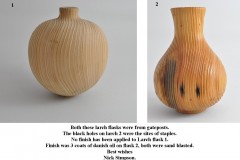

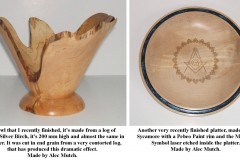

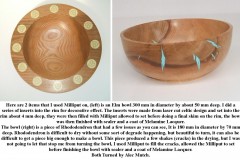

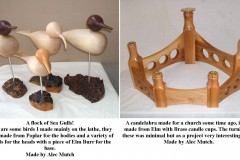

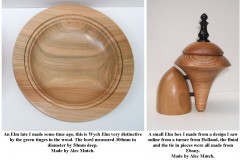

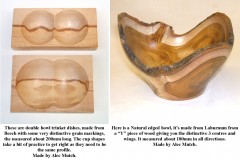

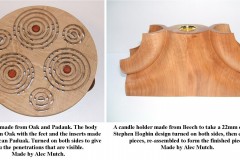

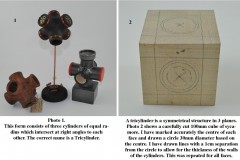

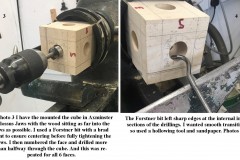

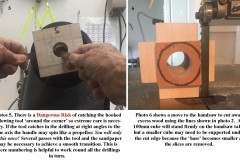

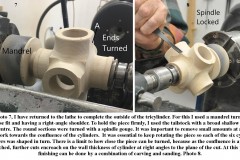

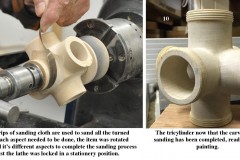

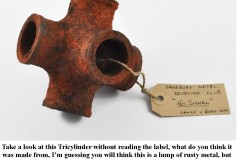

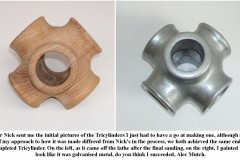

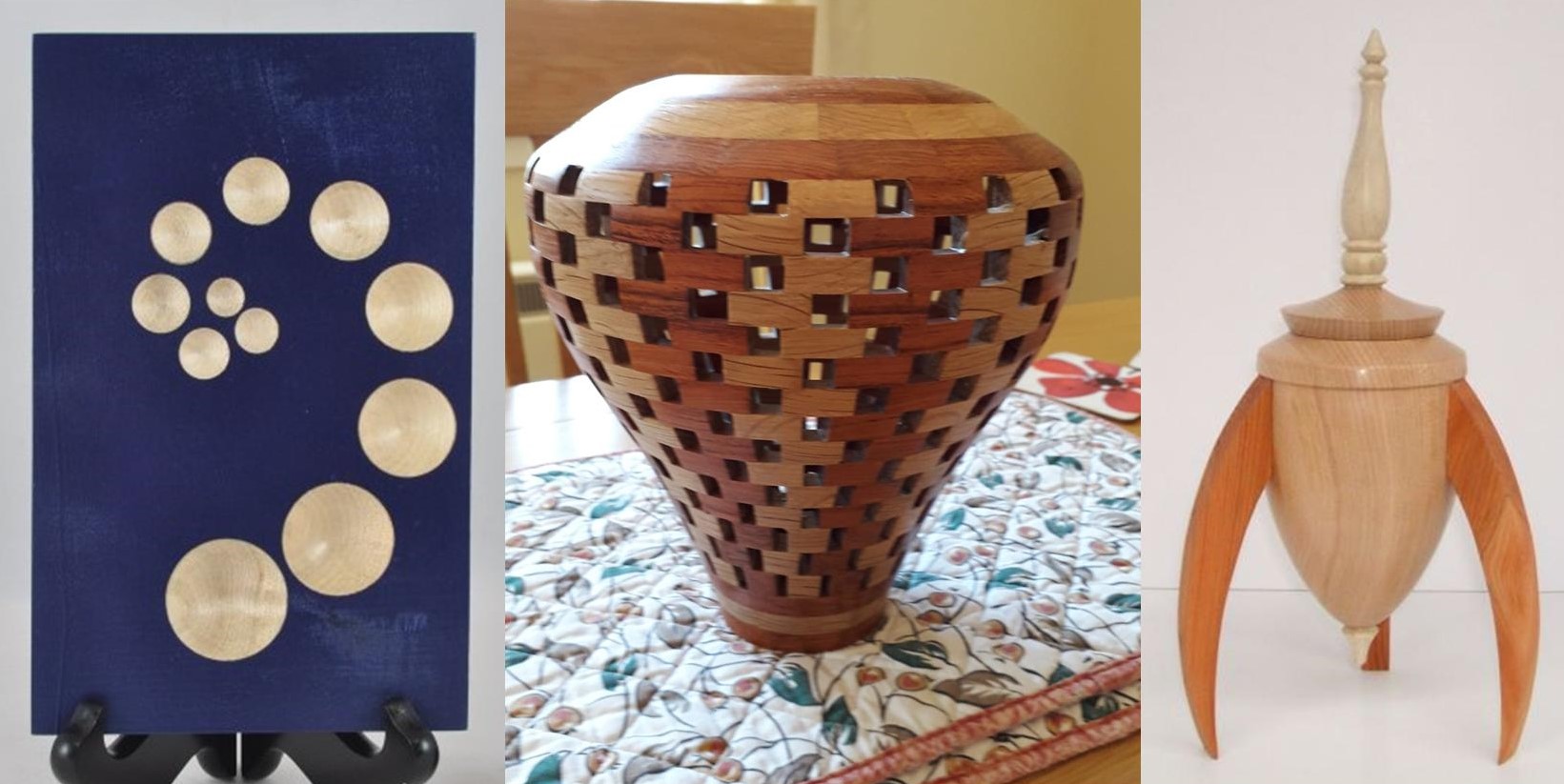

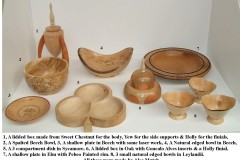

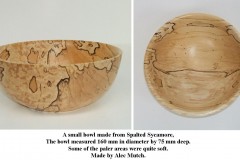

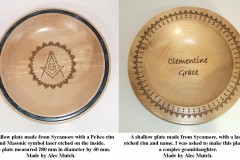

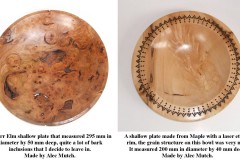

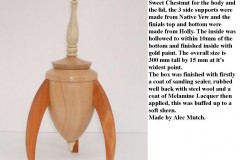

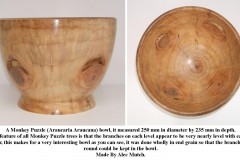

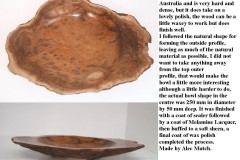

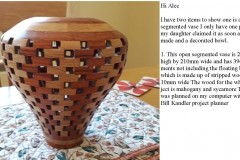

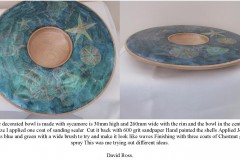

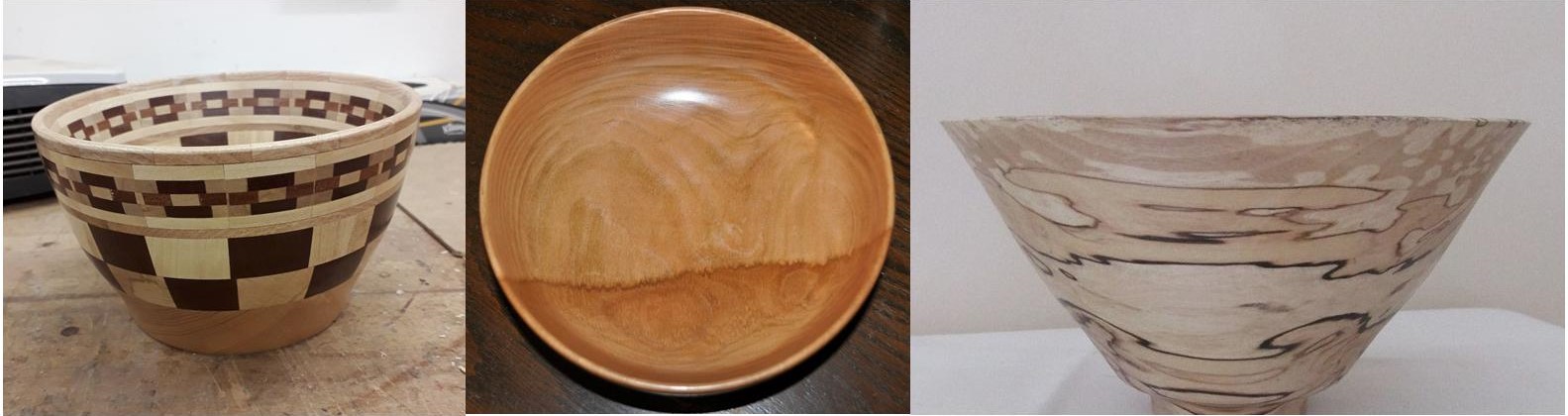

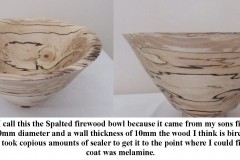

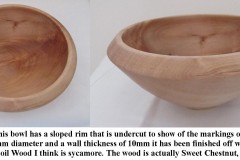

I will give you some pictures of the type of thing you could make, the first picture has quite a few boxes you could use for ideas, the second lot of pictures will be in a picture gallery of individual boxes with some instructions on how they were made. Pick a box or 2 from any of the pictures and see if you can make one or 2 similar.

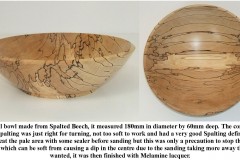

The picture Gallery follows, here you will see 10 different boxes with some instruction on how they were made. Just click any of the pictures to get a bigger picture and to be able to read the text.

Come on everyone make a box or 2 and make Cliff happy, you have no excuse if it’s ideas you need you have them here.

Once you make your box or boxes, send your pictures to me at;

a.j.mutch4321@btintenet.com

You have until Friday the 13th November 2020 to get your entries to me for publication on our club web site. I look forward to seeing them.

Do remember the clubhouse remains closed.