Start Time 6.45pm.

Our next meeting is on Thursday 22nd August 2024, organized by me and will be about off centre or multi centre work on the lathe. I have done this at a previous meeting but with all the changes in personnel in our club I felt this needed to be repeated.

I am doing this as a solo demonstration due to the fact some of the equipment required you may not have seen before. I will start the meeting with a very simple way of using the multi centre approach to alter the look of something being turned, this requires no specialist equipment all that’s required is a 4 jaw chuck and a revolving tail centre, both of which you will have already. However there are a few very specialised pieces of kit that you can buy to create some very interesting shapes, 2 of which I will show you and use, time allowed.

Here are a few pictures of what to expect.

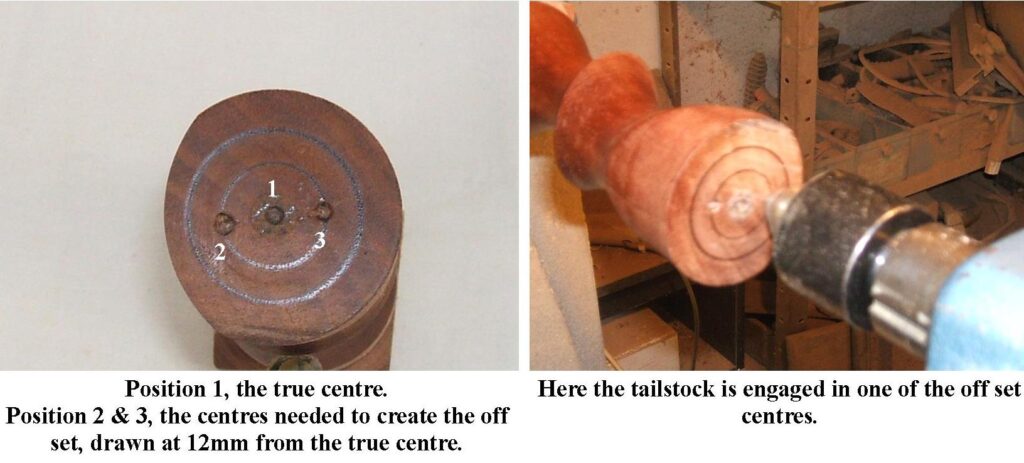

This is probably the easiest way to use the multi centre approach, start with a square piece of wood and set it into the 4 jaw chuck, that should determine the size for you, the length can be anything you like, I turned the spindle to the round apart from the part that is in the chuck, that needs to be left square, using the centre marked as 1, I then marked 2 more centres drawn 12mm from centre 1, (positions 2 & 3), the outer pencil line is the finished size at the top. Picture right, shows the tailstock in position 2 ready to start the shaping, it would be moved to position 3 for the 2nd turning.

In these 2 pictures you will see the ghost effect created by moving the centres, don’t get too ambitious when making the initial cuts. take it easy until you reach the actual round again. You will also see the square part held in the jaws of the chuck, it’s important to keep this square until you have finished moving the centres, that’s achieved by releasing the jaws enough to allow for the centre points to be changed, then tightened up again.

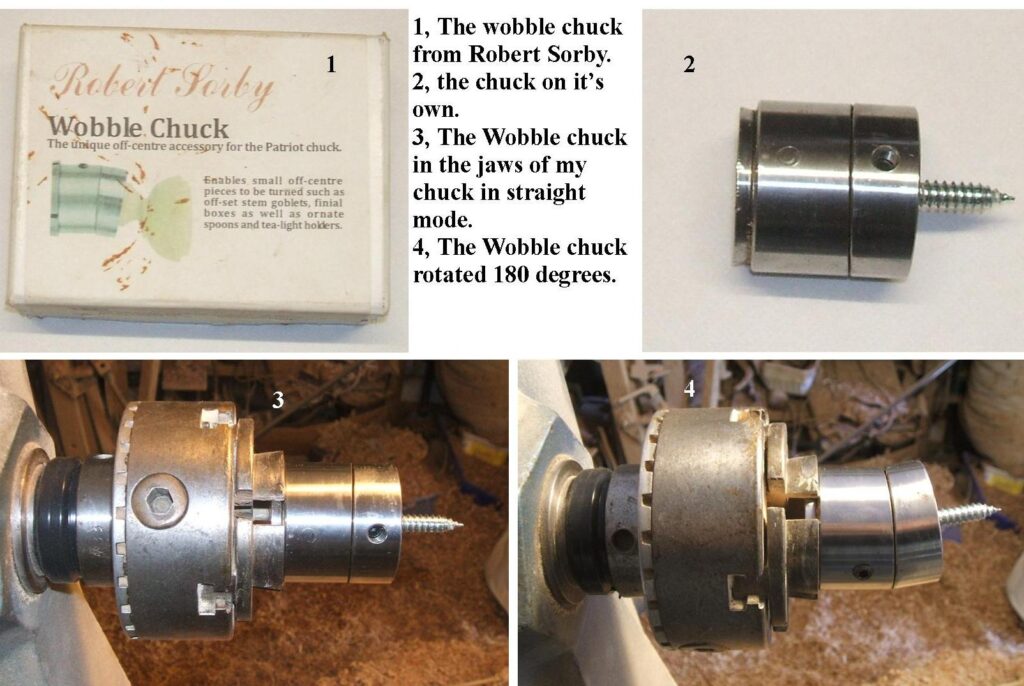

This is the Sorby Wobble Chuck, a small but very useful piece of kit, not expensive, fits in the jaws of the chuck and can be altered to produce some interesting shapes, some of which you may find hard to believe they have been done on a lathe with this piece of kit.

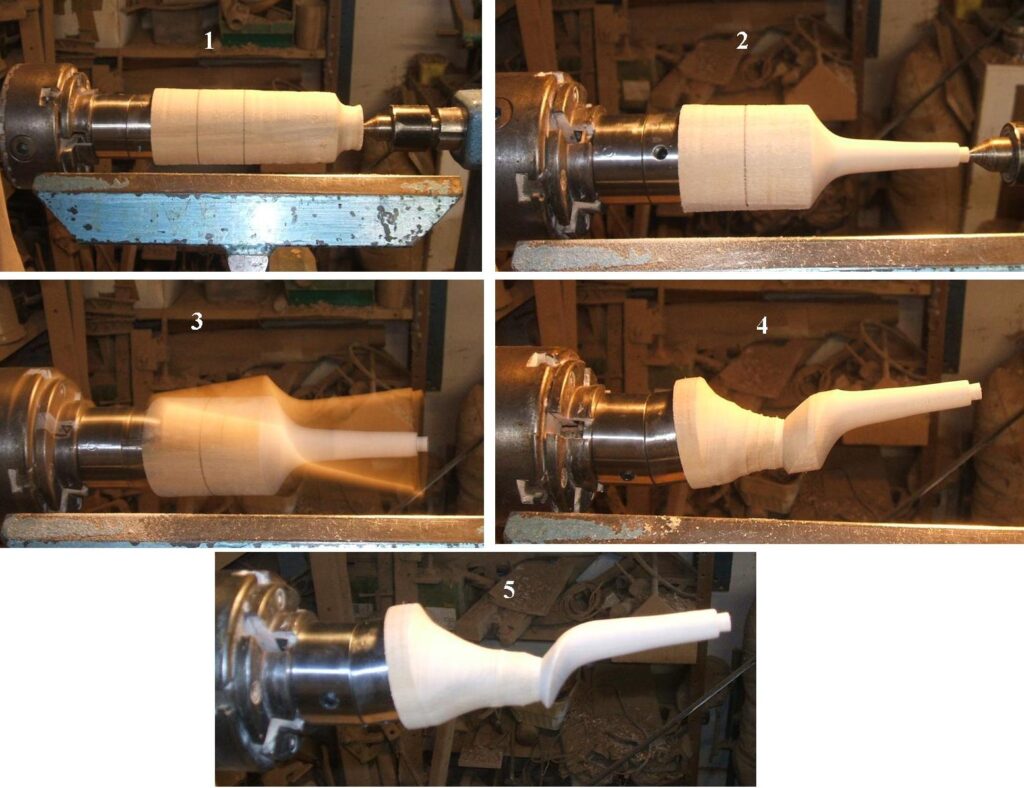

Here is the Sorby Wobble Chuck in action. 1 to 5 show the process in making part of the handle for a spoon.

Below is the Vicmarc Eccentric Chuck.

The Vicmarc Eccentric chuck in the lathe, Position 1, in the centre position, the wood gets fitted tight into the cup and secured with 2 screws. Position 2, the cup now off set by 12mm, Picture 3 shows a faceplate has been added and Picture 4, shows the faceplate also off set.

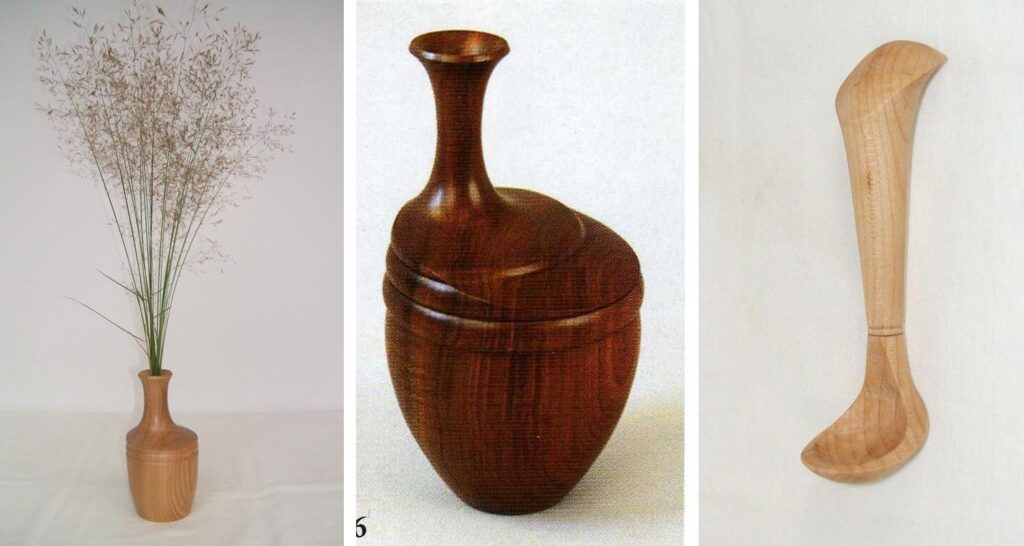

Here are 3 items made with the Eccentric Chuck and the Wobble Chuck.

I will endeavour to show you how these pieces of kit all work some by explanation others by example, questions will be addressed when asked, a foray into off centre or multi centre turning opens up a whole new set of challenges but is interesting to do. I look forward to seeing you all there.

Tea and Coffee will be available as will the usual raffles, you will all get a seat for this meeting and the tv screens might be useful to see the details up close.