Our latest meeting on Thursday 20th March was a solo presentation by Dave Line on the art of Segmented or Polychromatic assemblies. This art relies on using many pieces of woods of various colours that have to be cut to very accurate tolerances in order to make some of the items featured here.

To cut and make the pieces required some normal tools are used, but there are some tools that can greatly assist with the accuracy some of which Dave will show in operation. A few of these tools can be made by the user and Dave brought along a couple of them, explaining how they were made and how they were used.

Dave spent the first part of his presentation mainly showing paper designs for how the segments were made and to calculate how many pieces were required. He went on to show some of the plain rings that were cut and assembled pointing out some failings in one of the rings, this was a deliberate ploy to show just how accurate the segments needed to be in order for the whole assembly to go together and stay together. He also showed what he called a “feature ring” that was made up from a lot of very small pieces to create an interesting design. A cut only sample was handed round along with another that had been glued in order for the members to see and feel a segment of the featured ring.

He then started to talk about how the individual rings were then prepared by sanding both sides to an even surface and then how the rings were mounted on each other for gluing, some of the gluing could be done on the lathe by using the tail stock as a clamp, he had also brought along a home made frame that included in it a car jack that he used for clamping the rings.

I’ll take you through some of the items mentioned above by way of a few pictures and a little text.

Left, this is Dave Line making his opening remarks, with him on the table is some of the paper drawings Dave used for this type of work. Also on the table is his sanding machine that he uses to get the segments to the correct profile, he explained that some additional support was needed to the guides in order for them to reach the sanding surface. Right, here Dave can be seen explaining how the rings go together and how they are held, by using plastic tie bands. Also on the table is the home made press that Dave uses for clamping the rings whilst gluing. As you can see it’s fairly simple to make but you will need to get a car scissor or hydraulic jack .

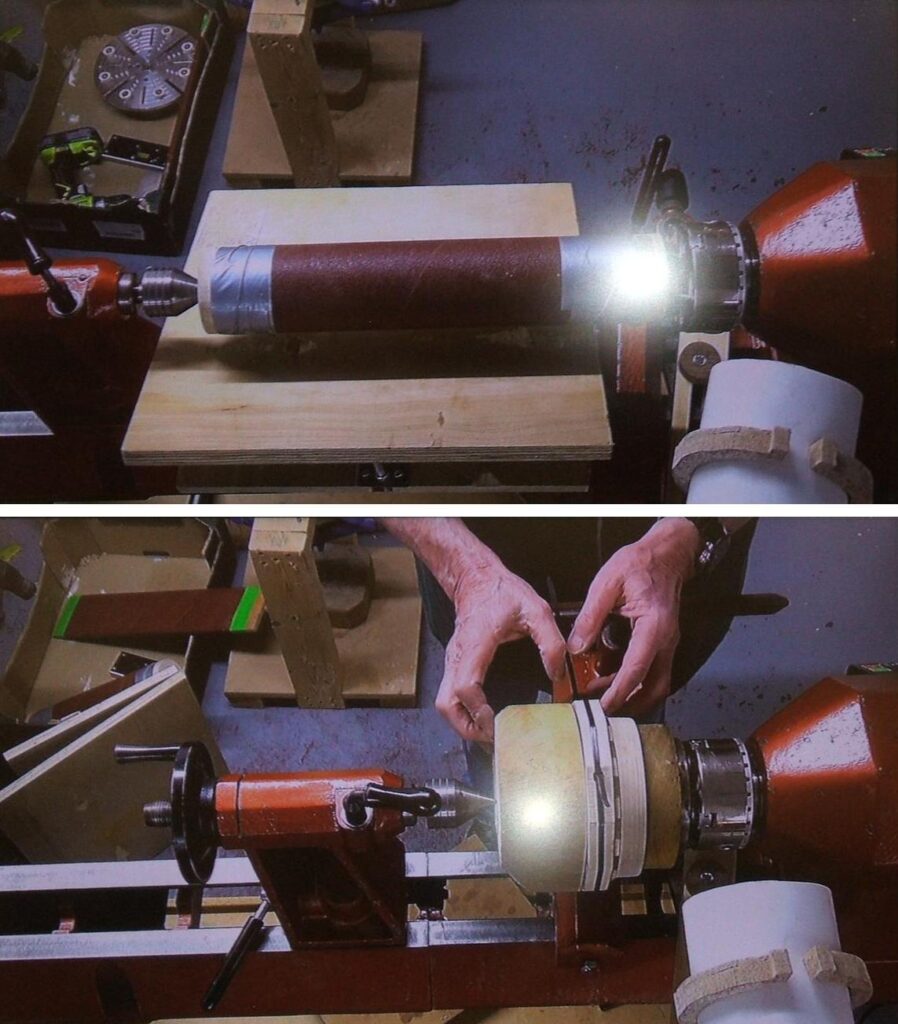

Top, another of Dave’s home made inventions: this he uses to get all the rings absolutely flat, it’s all done on the lathe with a wooden table fixed to the lathe bed and the drum held in between centres and used with the lathe running and guiding the ring through by hand. Below, another method of clamping whilst gluing, again using just the lathe between centres and a spare disc to spread the pressure, tightening by use of the tail stock.

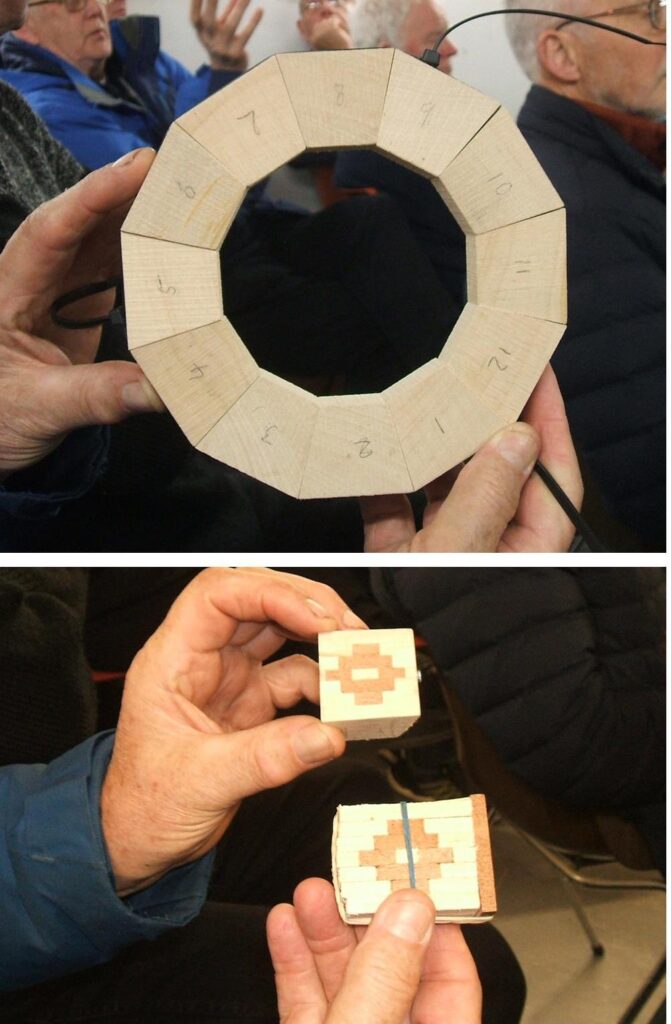

Top. a ring segment that Dave sent round the room, you will see what he means about accuracy, this ring was not acceptable, the gaps can clearly be seen between 9-10 an 10-11, some rework would be required, there needs to be no gaps. Bottom, 2 of Dave’s feature rings, the top one has been glued and shaped the lower one has been cut only and held by means of a solid support on the right hand side and a couple of elastic bands.

Top, a finished lidded form. Bottom, a selection of finished works by Dave Line.

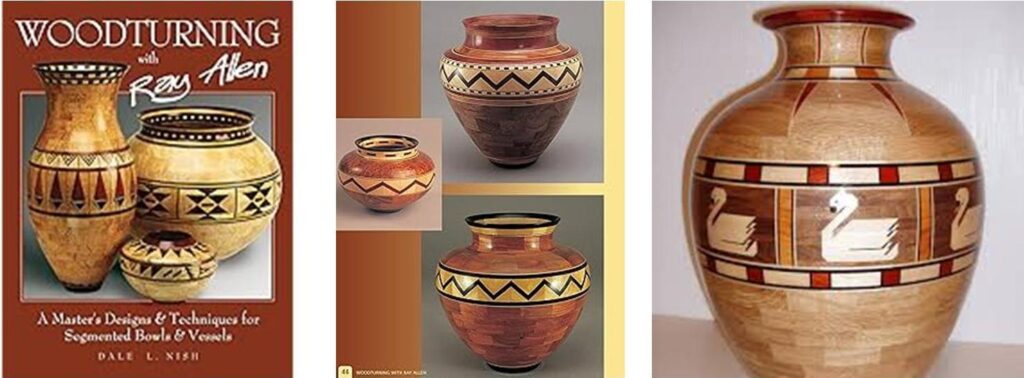

A book by Ray Allen on polychromatic assemblies and here are a few more items made using this very exacting art.

A big thank you to Dave for his presentation, I know he finds doing the presentation much more troublesome than just manning a lathe for the evening, so well done Dave and the members did appreciate all your efforts by giving him a huge round of applause.

Now for something much more serious, you all know that I am the author of the main blog for all the meetings, this entails doing an announcement along with some pictures of the next meeting. It then develops into doing the report on the actual meeting, this includes taking pictures and getting all the turners names and what they are doing. I have had some help with the pictures on the evenings when I’m on the lathe by Susan Drew and for that I am very thankful. The pictures then need to be edited, sized and presented into a web page, along with some text, I normally go for about 4 to 5 pictures from every lathe in use, more for solo presentations of up to 20.

I have been doing this for over 6 years now, it takes me up to 6 hours each week to do the blogs, normally my Sunday Morning is used to upload all the information, that has been processed the day before, editing. sizing, cropping and finally entering the text ready to upload.

As you are also aware I am not on the committee anymore, I have informed the new committee that I would continue to do the blog until the end of April 2025, that should have given time for someone new to put themselves forward to do the blog. Unfortunately no one has come forward to replace me.

If no one comes forward before the end of April the blog that I do I know has a lot of followers will cease to exist. If you would like to put yourself forward to do the blog, come and talk to me or speak to Nick Simpson your new chairman.