Our meeting on Thursday 9th May 2024 was organized by Keith Brown, Keith had arranged to have 4 turners demonstrating how to use some of the ancillary pieces of equipment that are available to woodturners, this also included some jigs that could be made by the turner to assist in their woodturning. The 5th Lathe was to be used by Daniel Stewart to demonstrate how to make some of the items that were to be made in the up and coming competition on the 23rd May 2024, a useful prelude to the competition.

Some of the turners were not actually demonstrating how the turning was done, they were showing and explaining how some of these ancillary pieces of equipment worked.

As I was one of the turners demonstrating I got David Hobson to take all the photographs, here are some of them with some text added.

Here we have Geoff Potter making a natural edged bowl from half a log, demonstrating how to first hold the piece, (curved surface towards the drive), also showing in Picture 2 how he dealt with the final pip on the base.

Here we have John Ruickbie using the Bowl Jaws to hold his work piece whilst he is marking out where the faceplate ring needs to be fitted. Picture 2, John is positioning the faceplate ring, it will be secured with 4 screws. This is necessary to allow John to work the inside of the bowl.

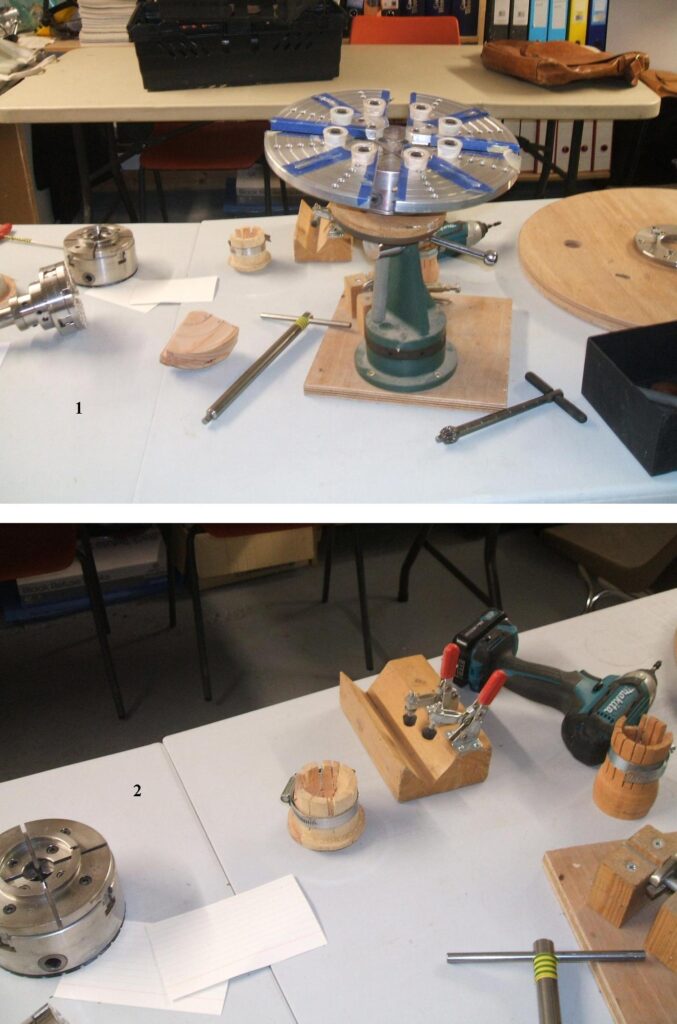

Picture 3, a piece of equipment John had made, this is a centre steady that can be fitted to the lathe bed to assist with keeping the work piece steady and to eliminate vibration. Picture 4, The big Bowl Jaws being used to hold a square piece of work, it’s not only available for turned work, this is an acceptable practice. Above the square piece is a sub assembly for a pierced piece of work, here you can see how the individual parts were assembled.

These items were brought in by Nick Simpson, they are all very useful for his turning, some are shop bought, most are home made jigs that Nick uses in his work. In picture 1, a set of Bowl Jaws could be used as a holding method whilst doing other work, acting as a 3rd hand. In picture 2, even the humble Jubilee is being used as an aid to Nick’s turning.

Picture 3, a Faceplate ring being fitted, it shows the four screws that were used. In picture 1 are a selection of turned ware that were on show from some of the turners.

Picture 1, Here I am showing how to skim the base of a box with it held between centres, the open end goes over the tapered jig, with the other end being held in the tailstock, this method is used to remove the spigot required to make the box. Picture 2, my method of making wooden mushrooms, hot melt glue onto a disc of wood and support the other end in the tailstock, a very slight taper on the glued end makes for a more interesting shape to the mushroom.

Picture 3, the almost complete mushroom, the pip at the tailstock end to remove, sand, seal and polish, then the mushroom can be parted off. Picture 4, I can be seen holding the mushroom fairly slackly whilst parting it off.

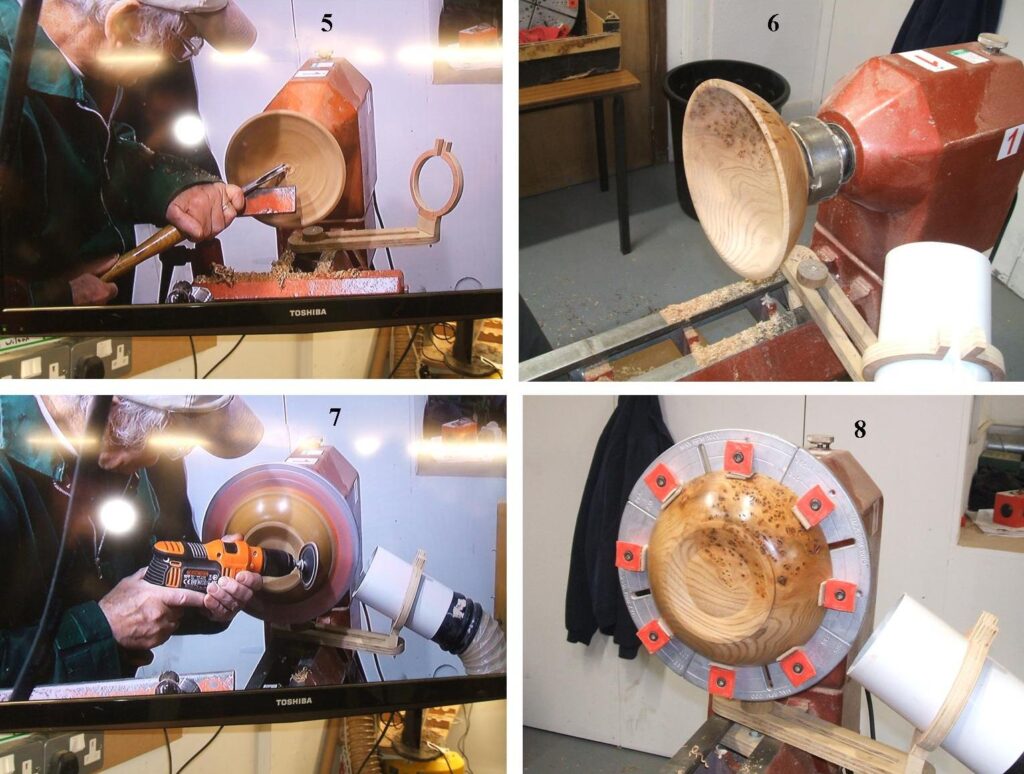

In pictures 5 to 8, the method of making a bowl using the Bowl Jaws, Picture 5, the inside of a bowl almost complete, it’s being held in a chuck recess for this part. Picture 6, the bowl after being sanded, ready to seal and polish. Picture 7, the Bowl Jaws in use, the piece turned around and the chuck recess re-worked to a decorative finish. Picture 8, the finished bowl.

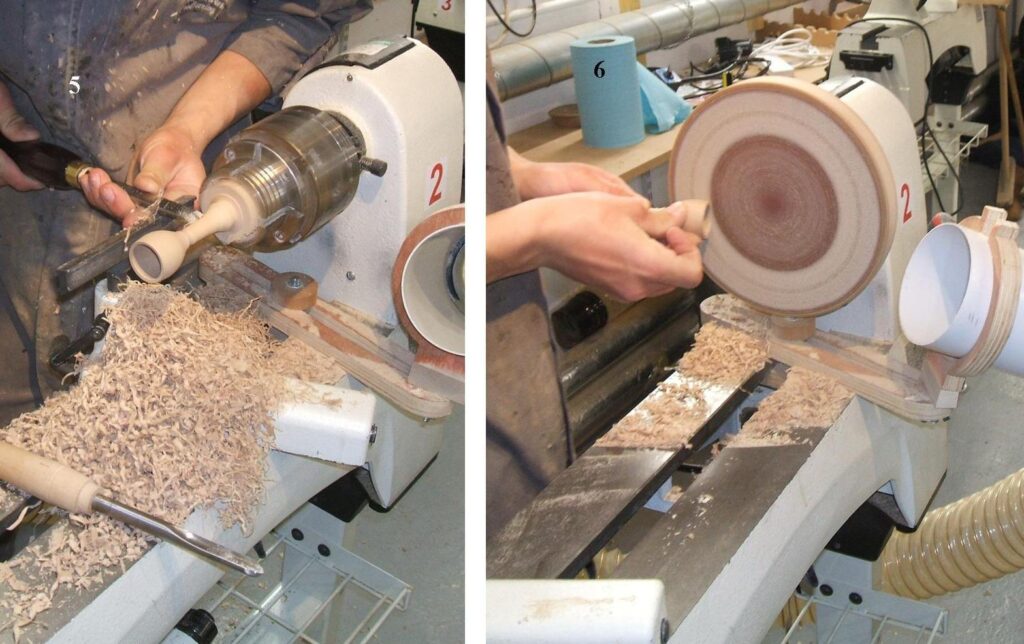

This last 4 sets of photo’s are all of Daniel Stewart whilst he was making wooden spoons, scoops and Ladle’s, all were being made from a pale hardwood such as Beech and Sycamore, these are Daniels first choices. This forward planning was to try to encourage more entries into the competitions by way of demonstrating how they were made.

We hope this demonstration was useful to our members, especially the items that Daniel was demonstrating in advance of the competition at the next meeting on the 23rd May 2024.

Do try and put in an entry to the competition, they do not need to be complicated, simplicity is sometimes best, and good luck if you do entre.

A vote of thanks went to Keith and to those doing the demonstrating at this meeting.