Our meeting this week was organized by Peter Lawrence, Peter had 4 turners (including himself) working the lathes mainly making items they had practiced at home, so some of the items were started at home to be finished at the club.

Peter was very new to demonstrating and was mentored by some of the more proficient turners from the club, this also applied to some more of the turners who were not so confident in what they were doing. This is exactly what we need to happen, this gives the less experienced turner the confidence to do a demonstration if they know someone will mentor them during any of our meetings. Peter received advice from several of the more experienced turners both on the use of the tools and the sharpness of them, I know he felt a lot more comfortable by the end of the session than he did at the start, this was also true for some of the others who were working the lathes.

As a follow on from our Fire Extinguisher talk at a recent meeting, Peter had organized for Joe Webster our First Aid and Fire Extinguisher manager to do a short demonstration actually using 2 different types of Fire Extinguishers, this was to show everyone what happens when you press the trigger and how long it lasts. It did startle some of the members who had not seen or used a Fire Extinguisher when Joe pressed the trigger. The Fire Extinguisher demonstration preceded the main event with the turnings.

I did manage to get some pictures at the meeting of both parts of the meeting, these are they.

The top 2 pictures show members of the club using the CO2 Fire Extinguisher, Joe demonstrated this first before asking for some volunteers to have a go, he explained this type of Fire Extinguisher only lasts a short time and you should always keep your back to the door when using it, never allow yourself to be trapped behind it after it’s been used. Bottom left, here is Joe demonstrating another type of Fire Extinguisher, this one used only water and not so startling as the CO2 Extinguisher to use. Bottom right, another of our club members using the Water Extinguisher.

Now for the turning part of the programme.

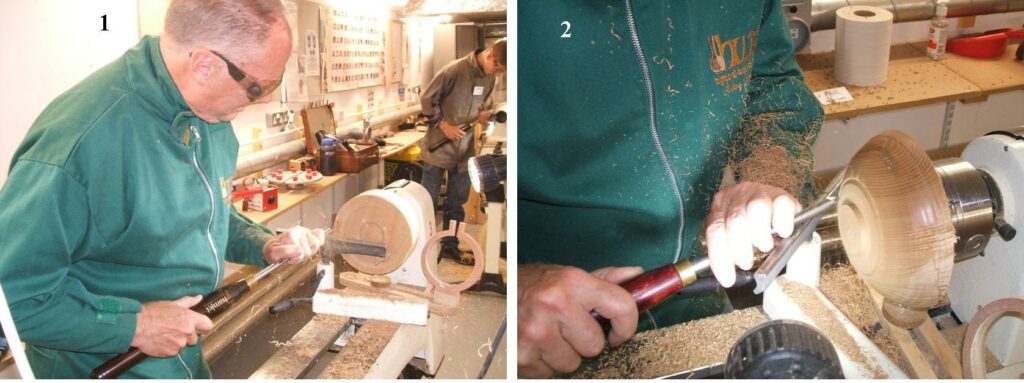

Picture 1, on lathe nr1 is Peter Lawrence setting up to start, Peter had done some of the preparation at home, he was using a piece of Spalted Beech that had a few issues that needed to be taken into account. Picture 2, here Peter is using a round nose scraper to open up the inside of a bowl, he did start with a bowl gouge but quite a significant fault could be seen on the outside, I was partly monitoring him and I felt he should use a tool that would put less strain on the wood, hence the scraper, he could take very fine cuts with this tool and avoid any untimely mishaps.

Picture 3, using the scraper, Peter had almost finished the inside of his bowl without any mishaps, his confidence seemed to grow with every passing cut he was making. He was also assisted by Richard Comfort who sharpened some of his tools. Picture 4, here we have Peter with his finished bowl. This was Peter’s first session on the club lathes and I know he felt a lot more comfortable after the session than he did at the start, this was all down to being given a bit of guidance from several of our members.

Picture 1, on lathe nr2 we had Susan Drew, working on a Spalted Beech bowl, she had prepared some of the work at home and was now shaping the outside of her bowl. Picture 2, shows Susan doing the final cut on the outside, the chuck recess has also been done, all that remains is to sand the outside before applying a finish.

Picture 3, here we see Susan working on the inside of her bowl using a bowl gouge, time slipped away a little too quickly for Susan and she had to stop and finish her bowl at home. Picture 4, you will see that she did manage to get most of the bowl done, but she did want to do a few more light cuts before sanding sealing and polishing, however she did agree to finish the bowl at home and bring it back to the club at our next meeting for all to see.

Picture 1, on lathe nr3 is Geoff Potter, Geoff was working on a piece of Elm, here he is truing up all the faces. Picture 2, Geoff has created a spigot on the bottom and is now working the shape on the outside with a bowl gouge.

Picture 3, Geoff finished the outside and turned the blank around and is now being held on the spigot, the hollowing is almost complete just a final cut in the centre before sanding. Picture 4, here is Geoff showing his finished bowl.

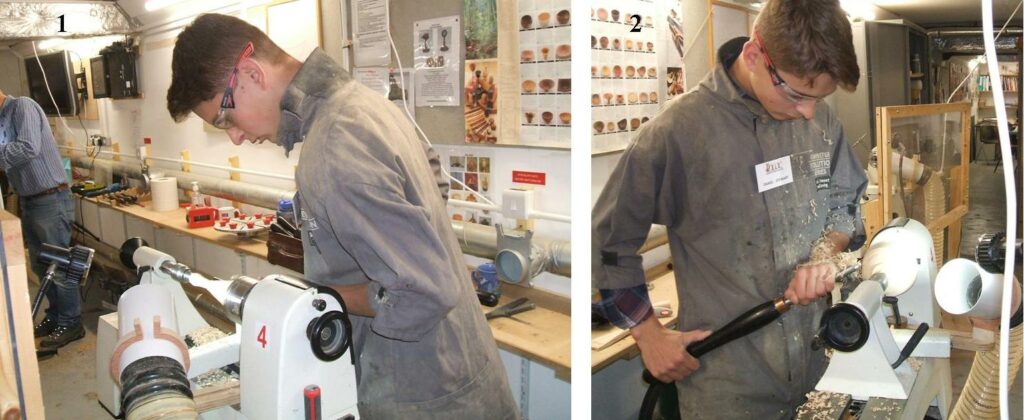

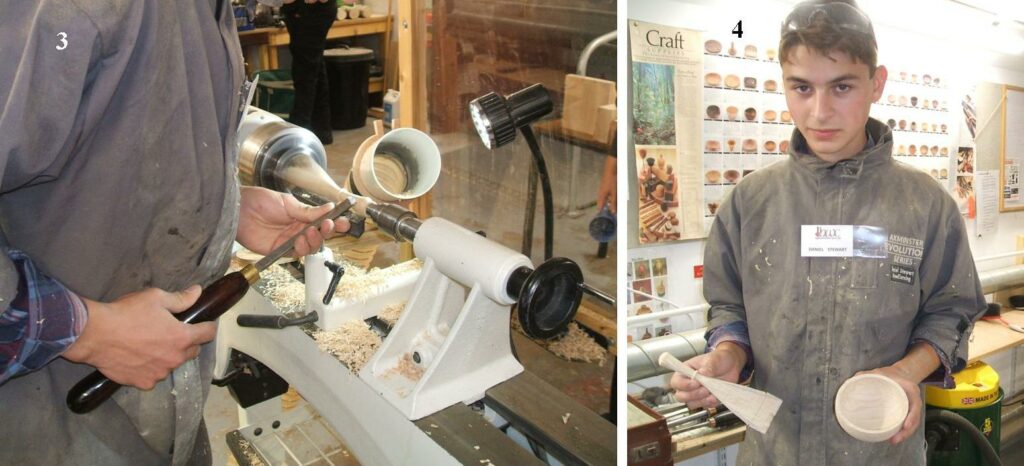

Picture 1, on lathe nr4 is Daniel Stewart, he was to make a pair of small bowls with some wooden cutlery, here he can be seen working on one of the cutlery items. Picture 2, Daniel has moved on to working one of the small bowls, the wood is Birch for all 4 items.

Picture 3, here Daniel returned to finishing off the cutlery pieces. Picture 4, here is Daniel with one of the sets of bowl and cutlery, he would go on the finally shape the cutlery pieces by hand. Depending on their use a coat of Food Safe Oil could be applied, or the items could be left sanded only with no further treatment required.

That concludes the meeting, it appeared to go very well for both the turners and the audience with lots of interest being shown by all the members.

Our next meeting is on the 14th September 2023, it’s the new look Showtime meeting, do take in your wares and remember to register with Errol Levings as soon as you arrive, Errol will then put you through what happens next.